Editor's Note - This feature by Jim Shepherd first appeared on July 19, 2024 on The Outdoor Wire.

We all suffer from what my instructor in the early days of computers called “information overload.” Too-much information delivered with too-little context.

There was no reliable way to discern the difference between real knowledge and regurgitated information.

The only thing that’s changed since then is the magnitude of both. Today, you can get “instant expertise” via Google along with a side of opinion disguised as fact, peddled with a heaping helping of emotion.

It’s more difficult to acquire the information essential to achieving knowledge. Knowledge takes time, regurgitation is as it sounds, nearly instantaneous.

To me, knowing a subject means being able to explain the complex in simple terms. That includes being able to demonstrate the difference between “upgrades” and marketing-based SKU “expansions” - and have no compunction about being honest about both.

Last week’s event with the MidwayUSA Foundation demonstrated the difference in no uncertain terms.

As I wrote in yesterday’s feature, the Vortex Edge instructors were more than capable of demonstrating the technology in the company’s optics. They were also capable of explaining why the technology mattered.

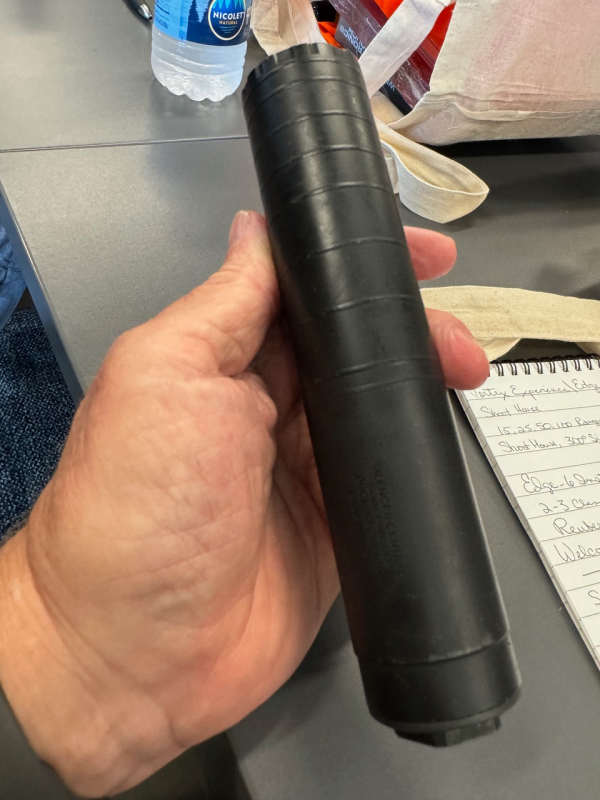

There were other experts at hand as well. The team from Silencer Central didn’t just explain how they’ve helped simplify the suppressor acquisition process from the legal side, they were on hand to help Vortex Edge Experience participants apply for their suppressor permits with the ATF. It’s one thing to hear someone talk about individual silencer ownership versus various “trusts” - seeing them explain it, then carry through the process was impactful.

Karter Keefer’s ability to explain different manufacturing techniques and the materials and assembly processes used in various suppressors helped us understand how gun “mufflers” are really as job specific as the mufflers on everything from cars to power tools. Advancement of 3D printing technologies explained why it’s better to “print” some products designed to hit certain price points. His explanations of trusts versus individual ownership of suppressors also enabled attendees to decide which was best for each of them.

For me, the session on Ruger’s new American Gen. II rifle corrected my misperception about the new gun. I have both, but knew the “old” rifle absolutely capable of outshooting my abilities. I suspected the “new” American might be more “SKU expansion” than new product development because I lacked essential “trigger time” on my own rifle.

After shooting for a while, there was a realization. I was, to use a very exact word, wrong.

Ruger engineer Mike Johnson was there to explain the upgrades. He should know, he worked on engineering them. He explained each of the several improvements, from a stiffened stock to a new trigger.

The stock “fit” better and the trigger was noticeably improved. It felt more like an aftermarket replacement than the one in my “old” American. Johnson also explained the best features of the “old” model weren’t ditched, they were augmented after feedback from buyers, shooters and Ruger’s own engineers.

The effectiveness of any shooting “system” (rifle, optic, etc..) is only proven in one way: by shooting it.

As MidwayUSA Executive Director Scott Reynolds had explained to me earlier, Vortex hadn’t been asked to provide their best, brightest or most expensive scope. Only to select “the Vortex optic that best fit the rifle and caliber.” They chose their Venom 3-15x44 FFP model.

As we used the Ruger rifles and those scopes, we crept our distances out from the 50 yard boresighting on the indoor ranges. As we transitioned to targets from 400 to 1,000 yards (and beyond), it was obvious the combination of rifle/scope in 6.5 Creedmoor was more than adequate to accomplish the vast majority of shooting/hunting situations any of us we were likely to encounter.

Not too long ago hitting targets at those distances required custom rifles, extremely expensive optics and lots of “fiddling” to get things tuned. Last weekend, every shooter hit their 1,000-yard goal with a rifle, optic and suppressor kit that cost under $2500 -including the AFT’s $200 tax stamp and establishment of a legal trust to own the suppressor.

That’s less than the cost of most true custom rifles.

As I’ve written before, it’s a great time to be a shooter.

We’ll keep you posted.

— Jim Shepherd